Measurement of volume

Pipettes

Pipettes are used for a precise measurement of small volume of liquids. Pipettes are filled by sucking of the liquid by the mouth or by the various types of pipettors on the level above the volume mark printed on the pipette. Height of water column in the pipette is adjusted by draining of the part of the liquid up to the mark and then the liquid is released from the pipette into the vessel in which we want to dose the liquid. Longitudinal axis of the pipette must be in vertical position and the jet of the pipette may not touch the vessel wall and the vessel wall must be bent towards the longitudinal axis of the pipette. The pipettes are produced in two accuracy classes: AS with waiting time 5 seconds and B without waiting time.

Pipettes are adjusted to deliver of its indicated capacity; it means the volume measured by the pipette is the volume that runs out from the pipette. The rest of the liquid that remains on the pipette walls and in the jet is not included to the measured volume. The pipettes adjusted to the delivered capacity are marked on a label by the letters “Ex”.

Note:

If all liquid in the volumetric vessel is included into the measured volume, the products are marked on a label by the letters “In”. These vessels calibrated to contain.

There are two basic types of pipettes: volumetric and graduated pipettes. The volumetric pipettes are used for the dosing of nominal volume given on the pipette label. The graduated pipettes can dose any volume within the nominal pipette volume.

| Volumetric pipettes with nominal volume up to 100 ml are made from soda-lime glass. Volumetric pipettes with the volume up to 200 ml are produced from borosilicate glass. The pipettesare enlarged in the center part (pipettes with volume 1 and 2 ml are also produced without enlargement |

|

|

in the center part) and they have one graduation line on the upper part of the tube above the enlargement; in the case of two-sign pipettes could have one more graduation line on the tube part below the enlargement. The height of liquid level is adjusted after the filling the tube in such a way that meniscus will touch upper edge of the graduation line, see Figure No. 4.. Join of bottom edge of meniscus and eye must be perpendicular to the longitudinal axis of the pipette during the adjustment the meniscus, see Figure No.4. The liquid is then discharged from the pipette completely up to the jet of pipette, in case of two sign pipettes up to the second sign. In case of pipettes with B class of accuracy the dosing of measured volume can be stopped after the releasing of the liquid from the pipette. In case of pipettes with AS class of accuracy it is necessary to wait 5 seconds till the rest of liquid from the walls of pipette is released. |

Graduated pipettes of the volume up to 25 ml are made from soda-lime glass, graduated pipettes of the volume 50 and 100 ml are produced from borosilicate glass. The scale is printed by silkscreen printing on the tube and each tenth mark is numerated. The scale is divided in milliliters, pertinently in fractions of milliliters. Two types of graduated pipettes are produced: pipettes with full outflow and pipettes with partial outflow.

| In case of the pipettes with full outflow the height of water column after the filling of the pipette is adjusted in such way that meniscus will touch upper edge of volume mark (see Figure No. 5), which corresponds to the volume that we are going to measure. Then the liquid is released from the pipette. |

In case of pipettes with B class of accuracy the dosing of measured volume can be stopped after the releasing of the liquid from the pipette. In case of pipettes with AS class of accuracy it is necessary to wait 5 seconds till the rest of liquid from the walls of the pipette is released.

In case of the pipettes with partial outflow, the liquid level in the pipette is adjusted on the upper mark in such a way that meniscus will touch upper edge of the mark (see Figure No.5) and the liquid is released up to the mark whose value corresponds to the volume that we are going to measure. Pipettes with B class of accuracy enable to adjust immediately the liquid level in the pipette in such way that the meniscus will touch upper edge of the selected volume mark. We produce this type of pipettes only with B class of accuracy. |

|

|

Burettes

| Burettes are produced from borosilicate tubes. The tubes are calibrated and every tenth mark is numerated. The scale division is in milliliters, pertinently in fractions of milliliters. In order to improve |

|

|

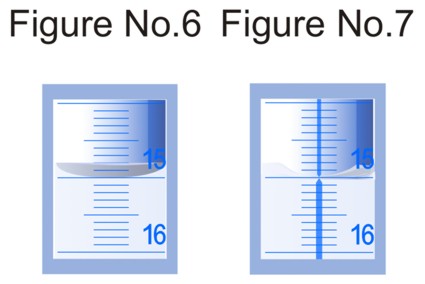

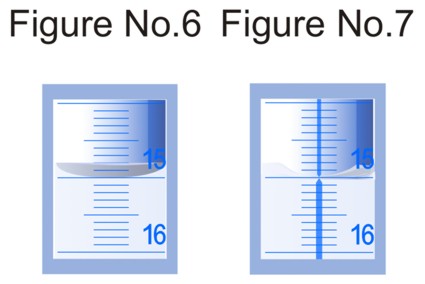

the reading of volume values on the burette, the tubes can have Schellbach strip (narrow blue strip overprinted by wider white strip) that is located on the tube opposite to the printed scale. Difference in reading on the burettes with Schellbach strip is illustrated on the Figures No. 6 and 7. While in case of burettes without the Schellbach strip the value is read similarly as in case of pipettes (on the lower edge of meniscus, see Figure No. 6), the burettes with the Schellbach strip show the read value between the heads of arrows that are created on the Schellbach strip by the influence of light refraction on the boundary between air and liquid, see Figure No.7. The |

| burettes are similarly as pipettes produced in two classes of accuracy: AS with waiting time 30 s and B without waiting time. |